HTM MACHINERY

Zero Point System: The Key to Improving Your Machining Time and Precision

Zero Point System: The Key to Improving Your Machining Time and Precision

In the manufacturing industry, precision and efficiency are the key factors determining any project’s success. In today’s competitive world, achieving maximum precision and efficiency is no longer an option but a necessity. This is where Zero Point System comes into play. Our brand’s Zero Point System has been designed to provide the perfect solution for all your manufacturing needs.

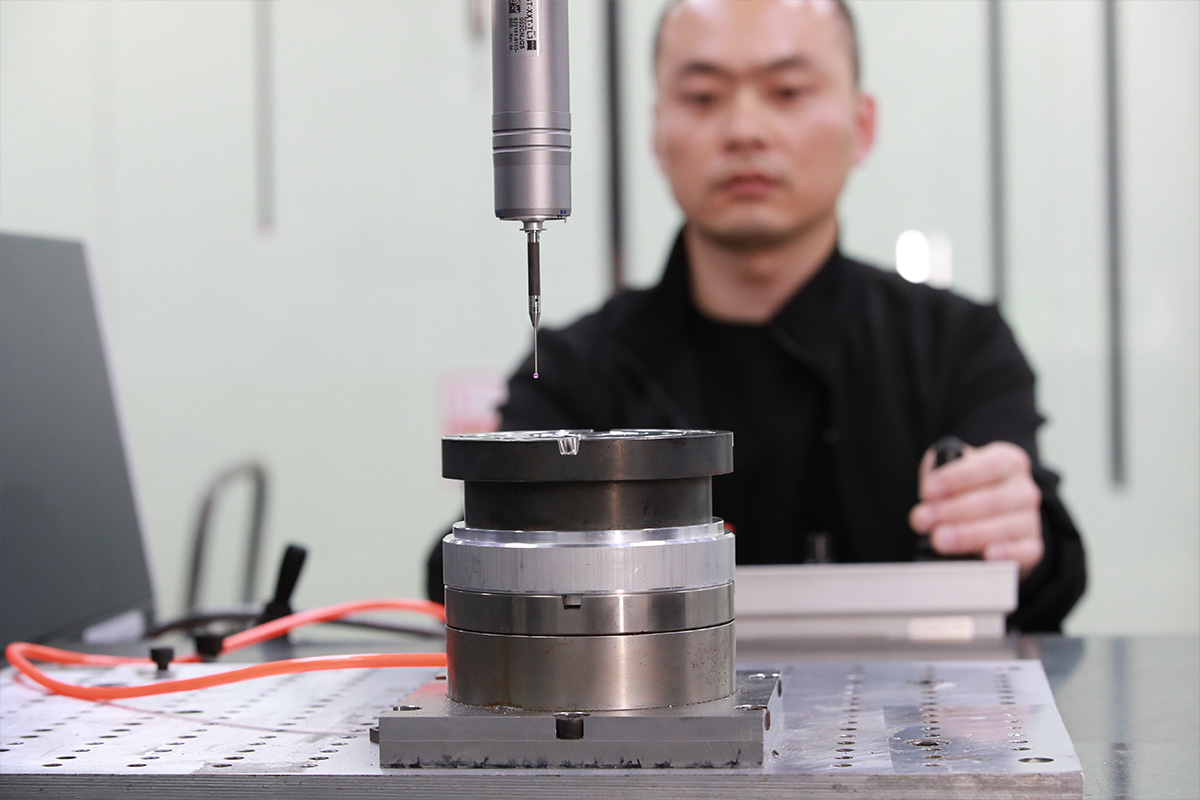

The Zero Point System is an innovative system that provides a secure and reliable method for quickly and accurately positioning workpieces on machine tables. Our system uses tungsten steel balls that provide superior hardness, wear resistance, and toughness, making them perfect for high-precision applications. Using tungsten steel balls also helps reduce tool wear and increase the service life of your machines, ultimately leading to lower costs and increased productivity.

In addition to using tungsten steel balls, our Zero Point System also incorporates a slider bevel positioning that can withstand up to 25 kN of force. This feature ensures that workpieces are securely placed, even during heavy machining operations. This improves the safety of your employees and reduces the risk of damage to your machines.

But the benefits of our Zero Point System don’t end there. Our system also includes a ceramic coating on its surface, providing excellent wear, corrosion, and heat resistance. The ceramic coating ensures that your workpieces remain in perfect condition, even after multiple machining operations, thus leading to a longer lifespan and reduced production costs.

Using the Zero Point System in manufacturing has significantly improved production efficiency and precision. By utilizing our system, manufacturers can significantly reduce setup times, allowing more time to be spent on actual production. The improved accuracy provided by our system also ensures that there is less scrap and rework, leading to a reduction in waste and an increase in productivity.

Overall, our brand’s Zero Point System is the ultimate solution for manufacturers looking to improve precision and efficiency in their operations. With its use of tungsten steel balls, slider bevel positioning, and ceramic coating, our system provides unparalleled durability, reliability, and accuracy. By incorporating Zero Point System into your manufacturing process, you can take advantage of its numerous benefits and stay ahead of the competition in today’s fast-paced industry.

Zero point system

Milling Cutter grinding machine

CNC machining

Milling Cutter Grinder

Milling Cutter Grinder