HTM MACHINERY

Milling Cutter Grinder

As with any mechanical equipment, proper maintenance and repair of your Milling Cutter Grinder is essential for ensuring long-lasting and efficient performance. Here are some tips on maintaining and repairing your Milling Cutter Grinder.

Regular Cleaning: Regular cleaning of your Milling Cutter Grinder is essential for maintaining its efficiency and performance. Make sure to clean the machine regularly, removing any debris, dust, or metal shavings that may have accumulated. Use compressed air or a brush to clean the exterior and interior of the machine.

Lubrication: Proper lubrication is necessary to keep the machine running smoothly. Make sure to lubricate all the moving parts of the machine, including the spindle, bearings, and gears. Use a high-quality lubricant that is recommended by the manufacturer.

Regular Inspection: Regular inspections can help identify any potential issues before they turn into major problems. Check for any signs of wear or damage and make repairs as necessary. Replace any damaged or worn-out parts as soon as possible.

Proper Storage: When not in use, make sure to store the Milling Cutter Grinder in a dry, clean, and secure location. Protect it from moisture, dust, and other environmental factors that can damage the machine.

Professional Repair: If your Milling Cutter Grinder needs repairs that you cannot perform yourself, it’s essential to seek out a professional repair service. Look for a service provider with experience in repairing milling cutter grinders, and make sure they have access to genuine replacement parts.

Grinding wheel maintenance: The grinding wheel is a critical component of the Milling Cutter Grinder. Our grinding wheel can last up to 1000 uses, which means you can grind 1000 Milling Cutter before needing to replace the wheel. However, you can also purchase your own grinding wheels. It’s important to keep the grinding wheel clean and free of debris, as this can affect the quality of your grinding. (Our Milling Cutter Grinder also includes a counter that keeps track of how many Milling Cutter have been sharpened. This allows you to easily track your machine’s usage and plan for maintenance accordingly. With proper maintenance and care, your Milling Cutter Grinder can provide reliable, high-quality grinding for years to come.)

In conclusion, proper maintenance and repair are critical to ensuring your Milling Cutter Grinder runs smoothly and efficiently. Follow these tips to keep your machine in top condition and avoid costly repairs and downtime. Remember to always refer to the manufacturer’s instructions and recommendations for proper maintenance and repair procedures.

HTM MACHINERY

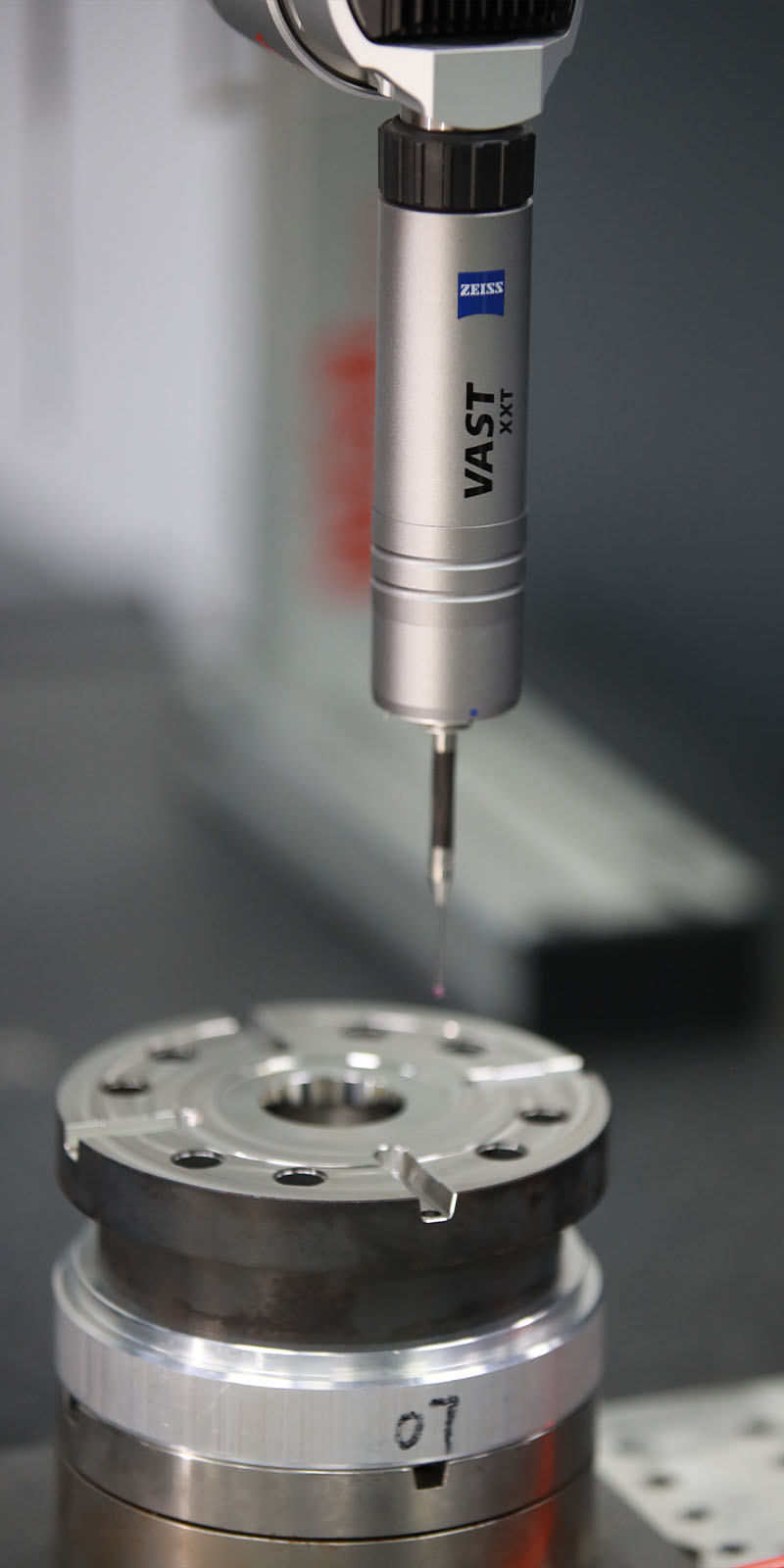

Zero Point System

is essential to ensure it functions optimally and extends its lifespan. Regular maintenance can prevent costly repairs and keep your system running smoothly, reducing downtime and increasing productivity. In this article, we will outline the necessary steps to repair and maintain your Zero Point System.

Cleaning: Regular cleaning is essential for the longevity of your Zero Point System. Ensure that the system is free from debris and contaminants. Clean the clamping modules and clamping pins with a soft cloth and a mild detergent. Be careful not to scratch the surface or damage the clamping mechanism.

Inspection: Inspect the Zero Point System for any signs of wear and tear, damage or misalignment. Check the clamping pins, modules and PVC coating for any cracks, chips or signs of damage. If you find any issues, contact a qualified technician to repair or replace the components.

Lubrication: Proper lubrication is essential for the smooth operation of the Zero Point System. Lubricate the clamping pins and modules with a suitable lubricant according to the manufacturer’s instructions.

Calibration: Calibrate the Zero Point System regularly to ensure its accuracy and precision. Use a dial test indicator to check the clamping force and repeatability of the system. If the results are outside the manufacturer’s specifications, adjust the clamping force or replace the components.

Replacement: Replace any damaged or worn components immediately to prevent further damage to the system. Zero Point System’s clamping modules and pins have a long lifespan, but they will eventually wear out and require replacement. When purchasing replacement parts, ensure that they are compatible with your system.

In conclusion, regular maintenance and repair of your Zero Point System is essential to ensure its longevity and optimal performance. By following these steps, you can keep your system running smoothly, reduce downtime and increase productivity. If you are unsure about any aspect of the repair or maintenance process, contact a qualified technician for assistance.

Get in touch with our expert

If you are interested in our product, please feel free to contact us